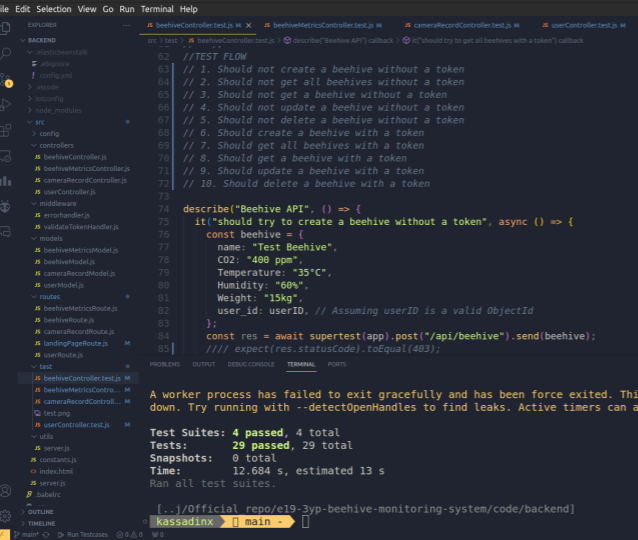

Software Testing - Beehive API Testing with Jest:

Ensuring the reliability and functionality of the Smart Beehive Monitoring System, our team engaged in rigorous software testing, specifically focusing on the Beehive API. Jest, a powerful JavaScript testing framework, became our tool of choice for this critical phase. Through a series of meticulously crafted test cases, we systematically assessed the API's response to various inputs, validating its accuracy and responsiveness. Jest's simplicity and efficiency allowed us to automate the testing process, swiftly identifying any discrepancies or anomalies. This meticulous API testing, complemented by Jest's robust features, played a pivotal role in fortifying the integrity of our system, ensuring it meets the highest standards of performance and reliability.